Our Refurbishment Process

PROFESSIONAL. RESTORATIVE. METICULOUS.

When an aga cooker enters our small workshop on the Scottish coast, every piece is inspected by our team.

When new, these classic models of Aga cooker would have been comprised of up to 70% recycled iron parts, like old gearboxes, lampposts etc. After decades of use, some parts of the cooker will be inevitably be destined for recycling, but we restore the majority - perfect for sustainability. No cookie-cutter, conventional cookers here!

Original, British-Made Aga Cookers that have stood the test of time.

We always use the original cast iron ovens, fronts and tops from the Coalbrookdale Iron Foundry. This was a 300-year old foundry, specialising in iron castings and famously produced Aga cookers since the 1940s. Unfortunately, the foundry was closed by the new American-owners of AGA Rangemaster in 2017. This is another reason why it's important to us that we use these original British castings!

Each one of our aga cookers is put through a vigorous restoration process. We use the same Vitreous Enamel techniques that have been used on Aga cookers for over a century. Glossy, hard-wearing and colourful, to match any kitchen decor.

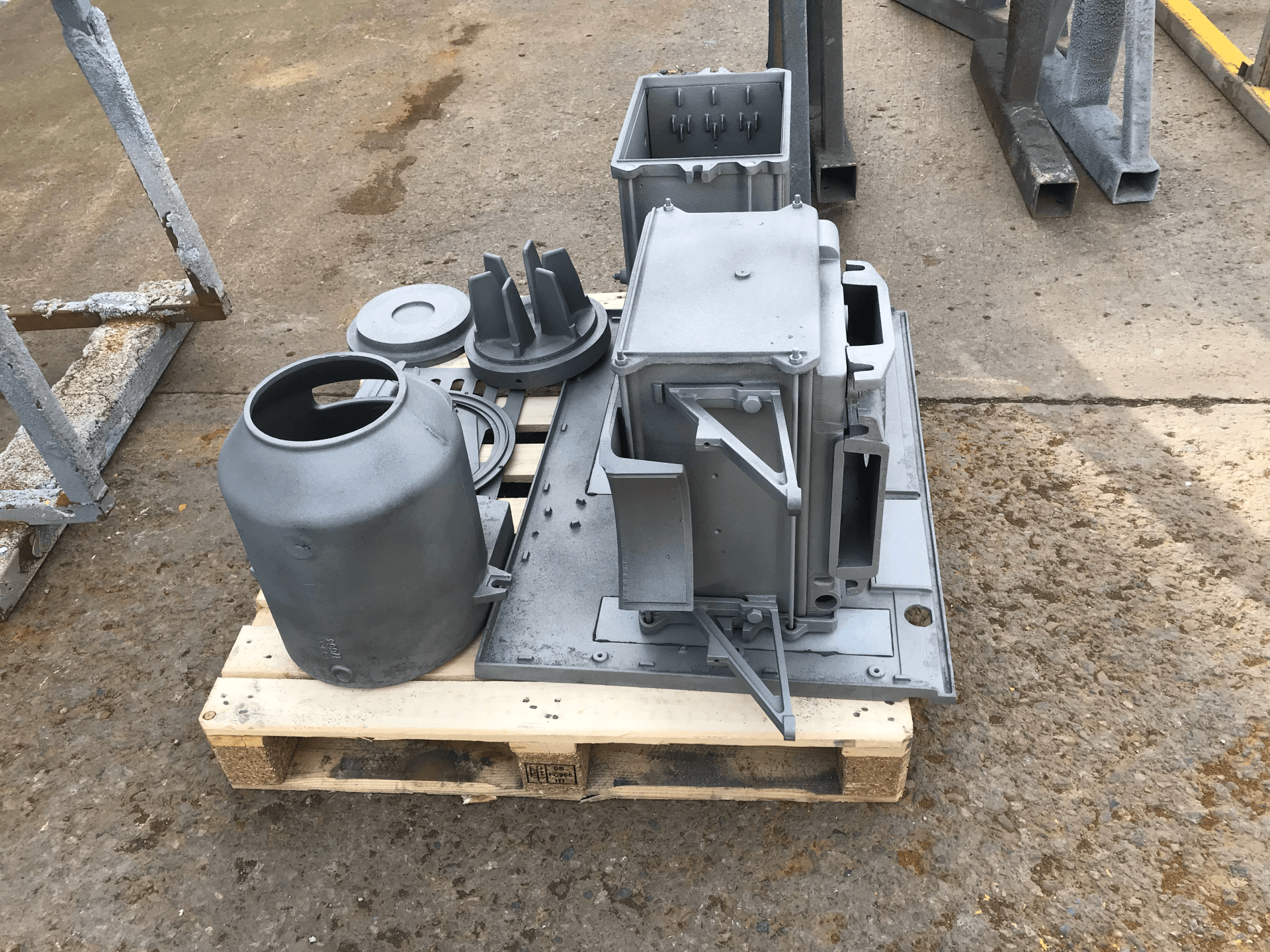

We use a mix of newly fabricated parts, freshly chromed fixings and shotblasted cast iron ovens to restore the cooker to showroom-quality condition.

STEP 1: DISMANTLING

The safe and efficient removal of an old Aga Cooker.

Our Refurbished Aga Cookers can start their lives as early as 1941! The model shown in the photographs here, could be as old as 1975. After a lifetime of use, the old, unwanted Aga Range Cooker is taken into our workshop for restoration.

Our engineers arrive onsite and professionally dismantle the cooker bit by bit, until it's completely stripped down. Inside the cooker is roughly 400 litres of loose-fill vermiculite. This is hoovered up and disposed of but don't worry, there is no known health hazard related to Vermiculite - we wouldn't want our engineers working with anything hazardous!

Once the Aga Range Cooker is stripped down, it's packaged into our van and brought back to our workshop for the restoration work to begin.

STEP 2: CAST IRON RESTORATION

Refurbishing the heart of the Aga Cooker.

All of our Refurbished Aga Range Cookers were originally forged at the 300-year-old Coalbrookdale Foundry in England.

This foundry was the original hub of Aga Range Cooker Manufacturing until the new American owners of AGA Rangemaster closed its doors in 2017. This was iconic British manufacturing at it's finest. The solid cast iron ovens are blasted with metal shot at high-speed, to remove dirt, grime or grease from years of use. Take a look at these before and after photographs from a couple of our restored Aga Range Cookers.

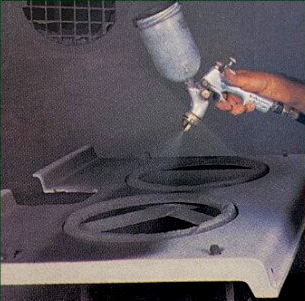

STEP 3: ENAMELLING

The Original Aga Range Cooker Enamelling Process

We do not paint our Aga Cookers. We believe the only way to restore these legendary cookers, is to stick to original processes used when they were first made, back in the 1920's.

Once you've placed your order for a Refurbished Aga Range Cooker and chosen one of our perfect enamel colours, we start the refurbishment process of the Front, Doors and Top.

The old enamel is shot blasted off to reveal the bare cast iron. The cast iron is then coated in the Vitreous Enamel that Aga Cookers are known for.

Vitreous Enamel is created by fusing coloured powder with substrate by hand, then firing the parts in huge furnaces. This process has been found to have been used as early as the 13th Century! There are even reports of the Titanic Captain's vitreous enamelled bathtub surviving its life underwater.

The result of all this hard work, is a glossy, luxurious and durable surface, ready for another lease of life as your 'new' refurbished Aga Range Cooker.

STEP 4: REPLACE, REFURBISH, REPAIR

The finishing touches to Aga Range Cooker Restoration.

As part of the refurbishment process, all parts are inspected and either repaired, replaced or refurbished. It's at this point that you can truly customise your reconditioned Aga Range Cooker.

You have the option of traditional chrome lids or colour-matched enamelled cast iron versions, antique brass or gold plated fittings, and even the style of badge on the front of your cooker. The aluminium door liners, lid liners and the chrome domes are all replaced, as well as seals and gaskets.

STEP 5: DELIVERY & ASSEMBLY

Professional assembly of your Aga Range Cooker.

Our traditional Oil and Gas Aga cookers are all supplied 'ex-works'. Professional assembly is required by your chosen installation engineer.

Our in-house engineers are highly skilled in our electric models, and have spent years perfecting the art of building these cast iron legendary cookers.

Our Refurbished Aga Range Cookers are delivered to you disassembled and are built up, right inside your kitchen. It's a very interesting sight to see all of the individual parts coming together to create a beautiful showroom-standard Aga Range cooker. A 2 oven Aga cooker weighs approximately half a ton in weight, and needs the correct seals and levels to operate efficiently - so we always prefer them to be assembled and commissioned onsite, the traditional way, rather than delivering in one piece and navigating them through doors and potentially disturbing delicate internal seals.

The installation usually takes a day to complete and once finished, you'll be left with your dream Aga Range Cooker, refurbished to perfection, and have saved THOUSANDS of pounds vs a brand new model (and tons of carbon emissions!).

You'll be sent our welcome documentation with a guide on how to get started, and how to register your parts and labour guarantee.

Eager to get started?

Browse our available models and choose which one is perfect for you.