A Refurbished Aga on a Loch

A first for us in Scotland - delivering and installing an aga cooker, on a very remote site, across a loch 🏴

Our client first got in touch with us a year prior, to source a refurbished aga cooker for their home outside of London. After chatting with them for a while, we all agreed the eControl Conversion System was the best fit for them; with the temperature control and no reliance on fossil fuels.

After we installed their 4 Oven Refurbished Aga Cooker in England, they were overjoyed! They loved the system and the experience of buying one of our refurbished models, so they agreed to place another eControl Converted model inside their Scottish home, to benefit from solar power.

It wasn't an ordinary Scottish home, though. This old manor house was tucked away on the shore of a remote loch, deep in the highlands.

Inaccessible by road, a landing craft boat is your only choice! Archie and I set off on the 4 hour drive to the meeting point on the side of the loch, taking in some lovely scenery on the way.

We unloaded the aga cooker from our van, and put it onto a pallet, piece by piece. It was loaded onto the landing craft and we jumped on too, for the roughly 20 minute jaunt across the loch. This is one of the benefits of the traditional models that we refurbish - they are all built up on site. This makes installation easier for those harder to reach sites, like a loch or in a tenement flat!.

In the video here, you can see the little buggy we had for crossing the terrain once we were on the other side.

Watch our Instagram Reel below:

Once we got to the other side, we unloaded and got to work. the whole build process takes quite a few hours, making sure the levels, seals and insulation are correctly installed for the best possible efficiency. Cookers with gaps in their insulation, or improper seals will leak heat like nobody's business!

The eControl electric elements are placed below and above each cast iron oven, to give you faster heat up times and direct heat where you need it. The ovens are then wrapped in the high-temperature insulating blanket, and once the top plate is fitted, the two independent hotplates are slid into place. Each of these have their own element, so that their usage doesn't affect the oven temperatures. Traditional 'always on' aga cookers are designed with one heat source, so the more you use the hotplates, the more heat is sucked out of your ovens. Not with our controllable electric options!

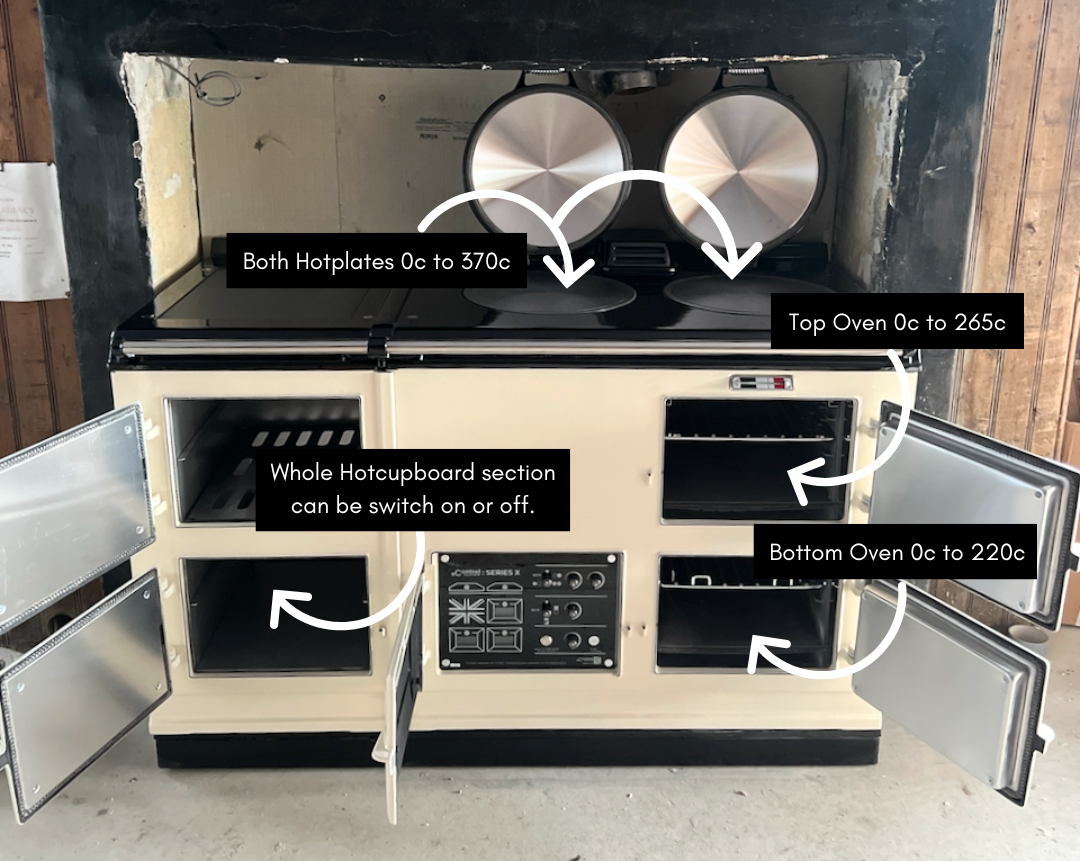

Here's a nice little diagram of this aga cooker, that kept me busy for 10 minutes or so! It shows each part of the cooker, and the flexibility that the eControl conversion offers, compared to the traditional models.

Some Further Reading: