Refurbished Aga Cooker in Edinburgh

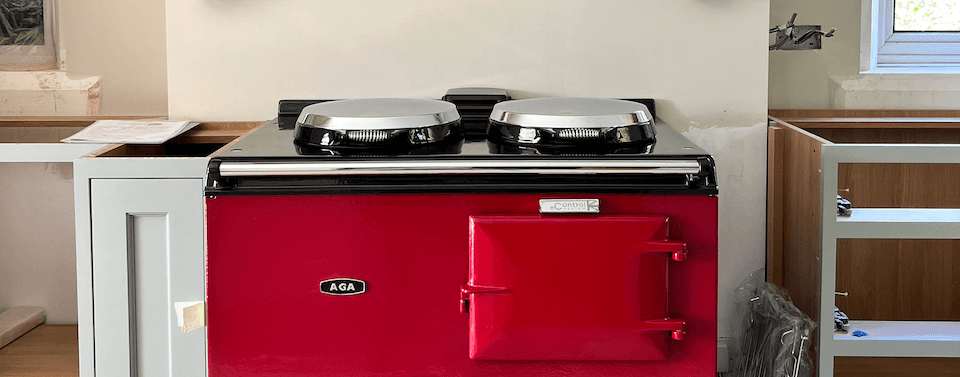

Steve and Steven (the saltire 'father-and-son duo'), recently had the joy of fitting a beautiful 2 Oven Claret eControl Aga Range Cooker in Edinburgh.

As you can see, it is a STUNNING pop of colour that immediately draws your eye to the heart of the home, the Aga Range Cooker. Luckily for the team, it was one of the rare sunny days in Scotland so they managed to stack all the parts outside to leave space for the other tradespeople. We're used to working alongside other teams during renovation projects and transforming spaces in no time.

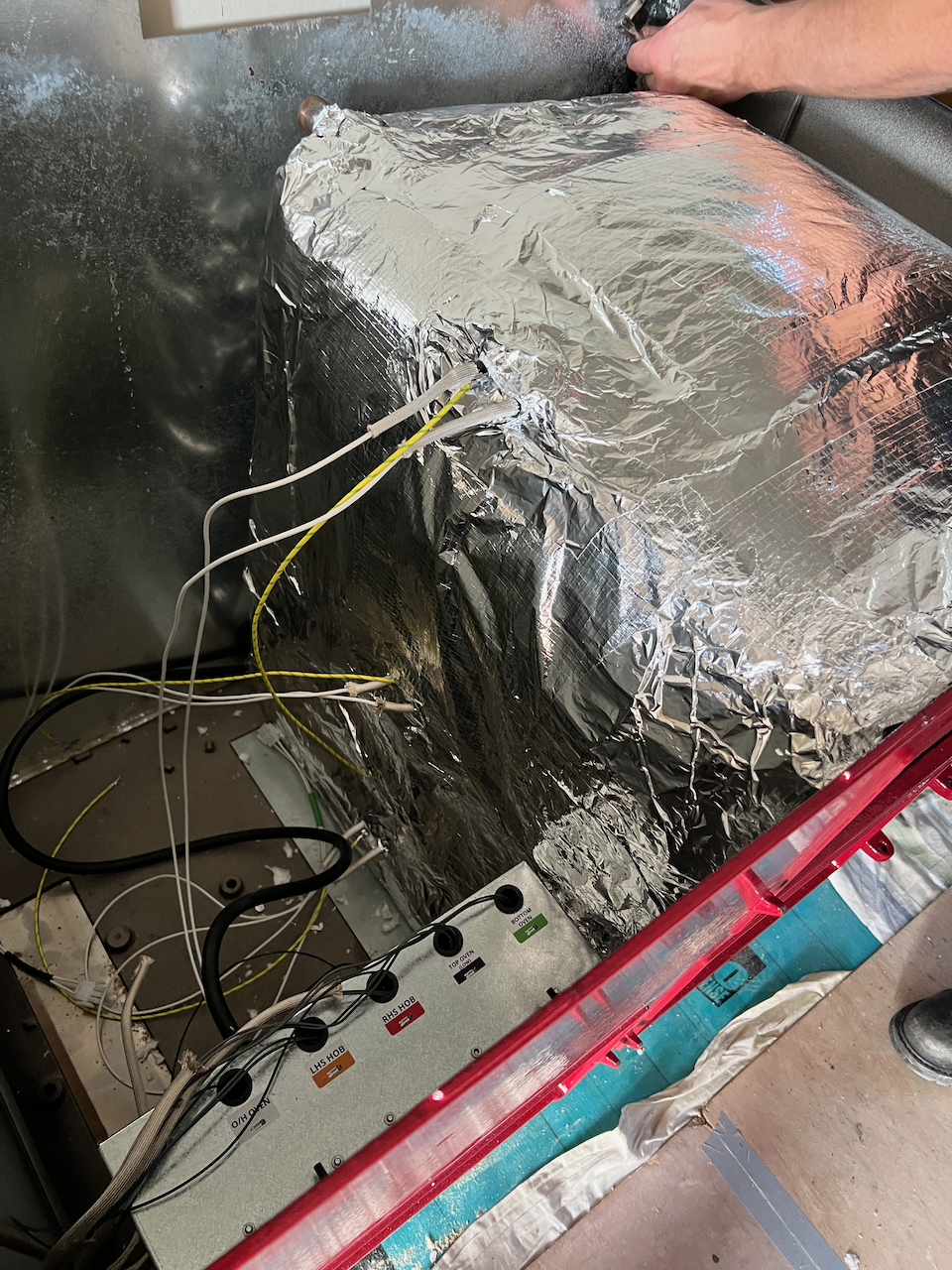

The build starts off as normal, with one of our adjustable plinths levelled, and the base plate placed on top. The ovens are built and modified slightly to allow the fittings of the temperature control stats. After that, both ovens are wrapped up before we can continue.

If you've had the opportunity to see one of our eControl conversions, then this 'space-age' contraption won't be new to you.

This is actually your Aga Range Cooker ovens! The same Coalbrookdale Cast Iron Ovens, but tightly wrapped in aerospace-specification insulation. This is what keeps the running costs of the eControl much easier on the purse strings!

You can see the 'tails' of the elements poking through the insulation, ready to be wired up. You have the top 1000w grilling element, the middle 750w element and the bottom 750w element. All working to create a great distribution of heat inside the ovens, without the long heat-up times of the traditional Aga Range Cookers.

Traditionally, the whole left side of the cooker would be filled with a Cast Iron 'ashpit' (where your heat source would sit), covered by a Cast Iron Outer Barrel (to channel the heat upwards), and a couple of Cast Iron ducts and conductions (to move the heat around the cooker). The modern elements and their placement, make these pieces redundant so you end up with a much more efficient Aga Range Cooker.

After the ovens are all snug, the rest of the stats and cables are seated, then the top plate is fitted. The last piece to the puzzle! The two hotplates are constructed and fitted into place, with individual elements underneath each one.

Before we leave, it's a quick tidy up, a loaded van and a demonstration, followed by customer Q&As.

This 2 Oven eControl Series 1 cooker has pride of place in this new kitchen. We hope it'll stay for decades to come and provide all the welcoming warmth and family memories Aga Range Cookers are known for.

If you're interested in your own fully refurbished Aga Range Cooker, just get in touch with us for a chat!

Some Further Reading: